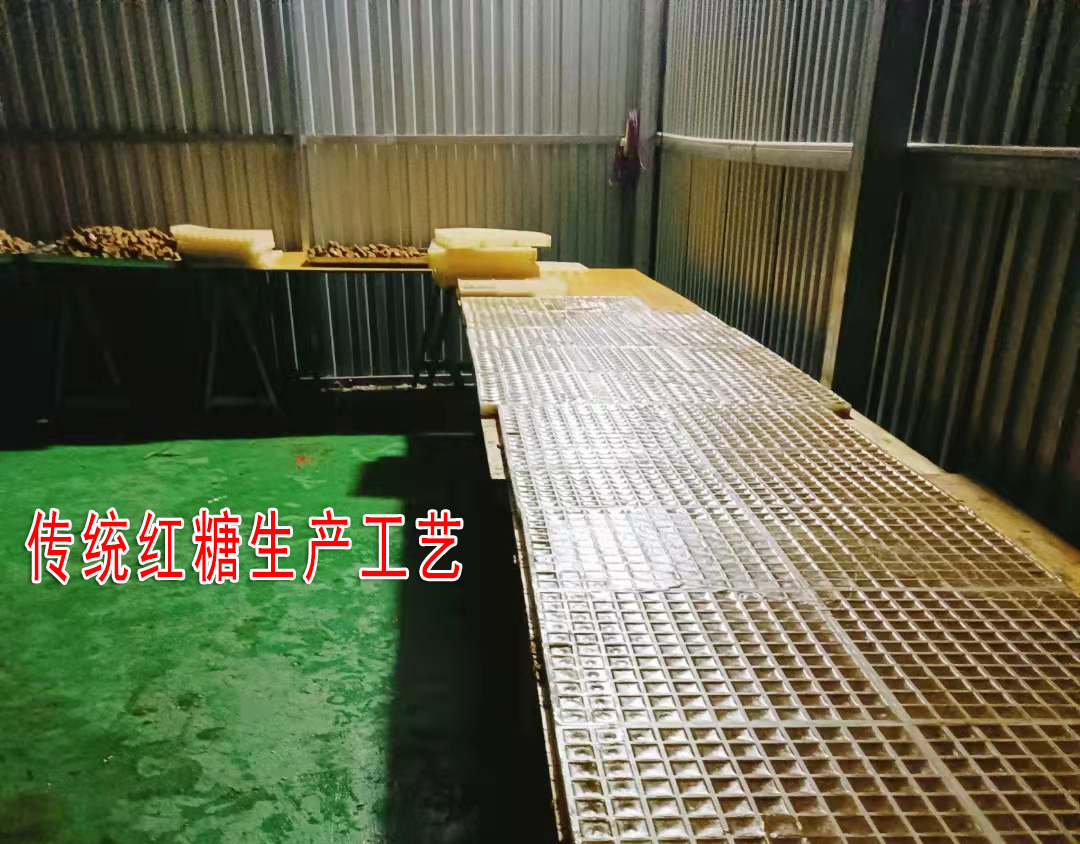

Processing steps of brown sugar:

1. Squeeze the juice from sugarcane, bring the juice to a boil with high heat to impurities and bacteria floating on the surface of the juice, and improve the cleanness and quality of the juice. This is the step of "opening the foam" and "sk the foam".

2. Simmer the juice over low heat and keep stirring to evaporate the water. The control of temperature is very important. This is the "drying water" process.

3. During the process of making sugarcane syrup, the concentration of sugar continues to increase, and it needs to be constantly until the sugar juice bubbles vigorously. At this time, you need to pay close attention to the viscosity, color, and crystallization degree of the sugar juice, and inject it the mold at the right time. After waiting for the high-concentration syrup to cool and solidify into a solid block of coarse sugar, it becomes a red sugar brick with hint of caramel flavor.

4. The red sugar is made by hand, with a natural and mellow fragrance, without preservatives, dyes, anti-caking, or additives. The longer the syrup is boiled during the production process, the darker the color of the red sugar brick becomes.

5. Cut the red sugar brick cubes and place them in a tray. Stack them in layers in the material rack, paying attention to the distance between layers. Push the material cart into the drying room and start the and humidity control system. During the use of the red sugar dryer, it can only heat up without dehumidifying for an hour because the humidity in the drying room is low at the beginning of the first stage. In the second stage, set the drying and dehumidifying work procedure mode. The red sugar dryer has a waste heat recovery function The heat generated during the dehumidification process will be reused in the thermal cycle of the drying room. The dehumidification process will not cause heat waste, thus the operating cost.

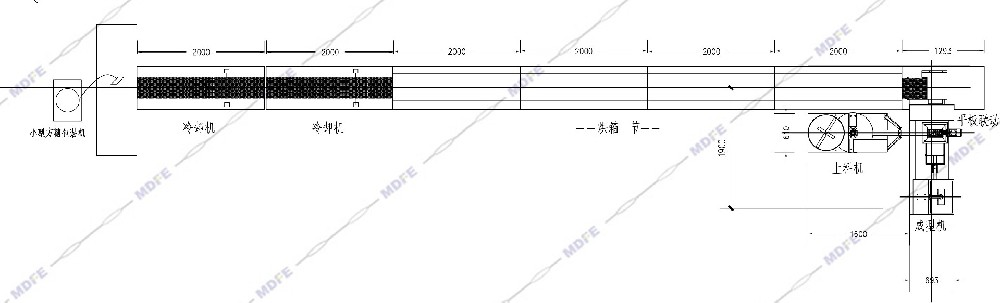

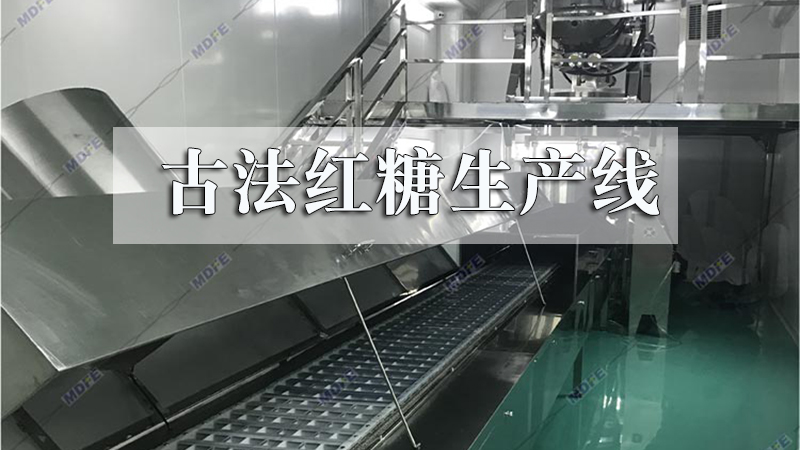

The process of red sugar processing is relatively complex, but don't panic. Now that we have the red sugar production line developed and manufactured by Mand Technology, the production of red sugar can be done in an integrated and automated manner. Moreover, the red sugar production line has the advantages of a variety of mold shapes, which are combined with traditional craft syrup that does not stick to the mold and modern computer control for fully automatic filling production.

Hangzhou Mandton Food Equipment Co., Ltd. an innovative food equipment manufacturing enterprise integrating R&D, sales, and after-sales services. It specializes in providing: coffee cube sugar hydraulic forming equipment, red sugar machine, black machine, red sugar production line, cube sugar machine, cube sugar production line, stuffing machine, filling machine, etc. Information hotline: 1338651568